Welcome to the official website of Shanghai Industrial Boiler Co., Ltd. / Shanghai Industrial Boiler (Wuxi) Co., Ltd.

-

-

WNS automatic fuel gas boilerSZS automatic fuel gas boilerLarge gas boiler

WNS automatic fuel gas boilerSZS automatic fuel gas boilerLarge gas boiler -

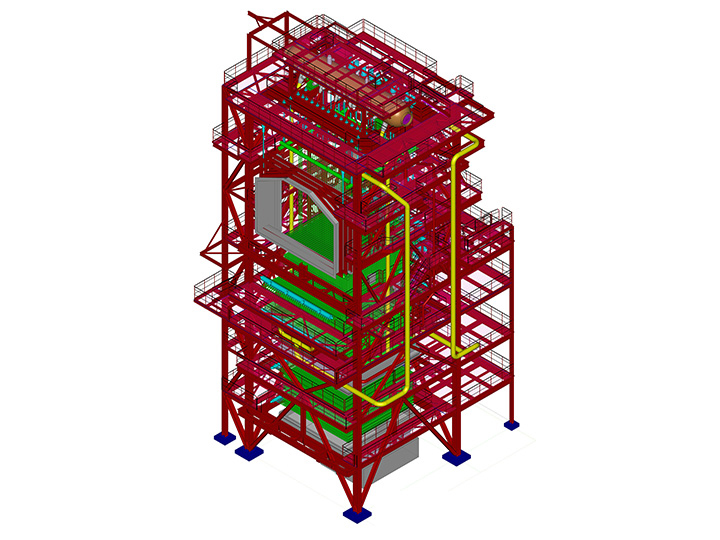

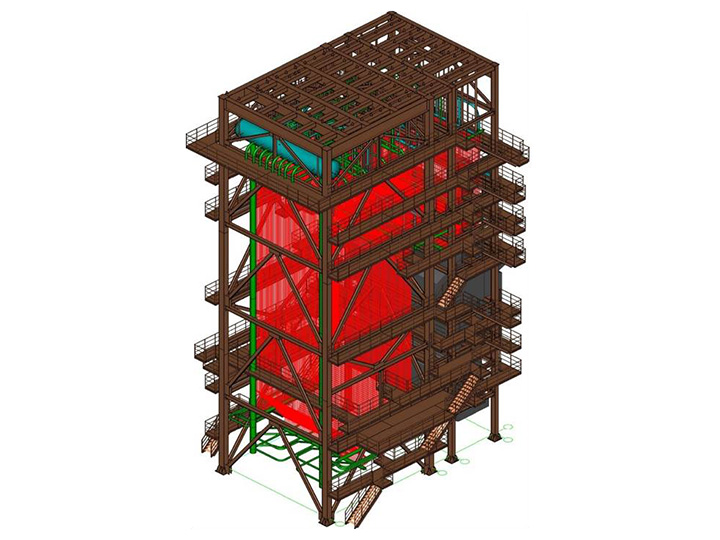

Circulating fluidized bed boiler

Coal-fired circulating fluidized bed boilerBiomass circulating fluidized bed boilerCirculating fluidized bed hot water boiler -

Biomass boiler

Biomass boiler -

Low temperature waste heat boilerSteel coking waste heat boilerNon-ferrous metallurgical waste heat boilerPetrochemical waste heat boilerCDQ waste heat boiler

Low temperature waste heat boilerSteel coking waste heat boilerNon-ferrous metallurgical waste heat boilerPetrochemical waste heat boilerCDQ waste heat boiler -

Efficient clean combustion industrial pulverized coal furnaceLarge power station pulverized coal boiler

Efficient clean combustion industrial pulverized coal furnaceLarge power station pulverized coal boiler -

Waste boilerAngle tube boilerFuel gas organic heat carrier boilerGrate type organic heat carrier boilerEfficient clean combustion coal powder organic heat carrier boiler

Waste boilerAngle tube boilerFuel gas organic heat carrier boilerGrate type organic heat carrier boilerEfficient clean combustion coal powder organic heat carrier boiler

-